Hardware components | |||||

| × | 1 | ||||

| × | 1 | |||

| × | 1 | |||

| × | 3 | |||

| × | 3 | |||

| × | 1 | |||

| × | 8 | |||

| × | 1 | |||

| × | 1 | |||

| × | 1 | |||

Software apps and online services | |||||

Hand tools and fabrication machines | |||||

| |||||

| |||||

While looking at projects on the Adafruit site, I came across a fruit machine project that has a cool 3D printed lever that incorporates its own return spring. The Adafruit fruit machine is built around a fairly large 32×64 RGB Matrix (4mm pitch) display. Since I had three 60mm x 60mm Red/Green LED matrixes that were left over from another project, I thought that I would modify my Matrix Slot Machine to incorporate this 3D printed lever.

- 1919 't slot' 3D Models. Every Day new 3D Models from all over the World. Click to find the best Results for t slot Models for your 3D Printer.

- Making a Slot Car With 3D Printing.: Hello, and welcome to my tutorial on how to 3D print your own slot car. Since the project depends heavily on what YOU want to make, I won't get into too much detail where it isn't needed.So, without further adeu, let's get started!

Video

STL files for 3D printing are oriented to print 'as-is' on FDM style machines. Parts are designed to 3D print without any support material. Original design source may be downloaded using the links below.

Design

The Red/Green matrix modules are common anode. Each matrix has 16 cathodes (8 red and 8 green). The cathodes are connected to a DM13A 16 Channel shift register with each output being a constant current LED driver. The anodes for each matrix are connected to a single set of 8 P-Channel MOSFETs which are driven by a 3 to 8 line decoder/driver so as to reduce the pin count needed for the microprocessor.

Building the display panel

I designed a PCB to hold the LED drivers and their associated components.

I have included the Eagle files in case you want to get the board commercially made or do as I did and make it yourself. I used the Toner method.

Start by adding the resistors, capacitors and MOSFETs.

Next add the links if you are using a single sided PCB

Best 3d Printing Machines

Solder on a 10pin header for the connections to the microprocessor board.

The 3 x DM13A and 1 x 74HC138 ICs are DIL variants. Their IC sockets have their pins flattened out and soldered to the board like a SMD device.

Finally add the red/green common anode matrix modules

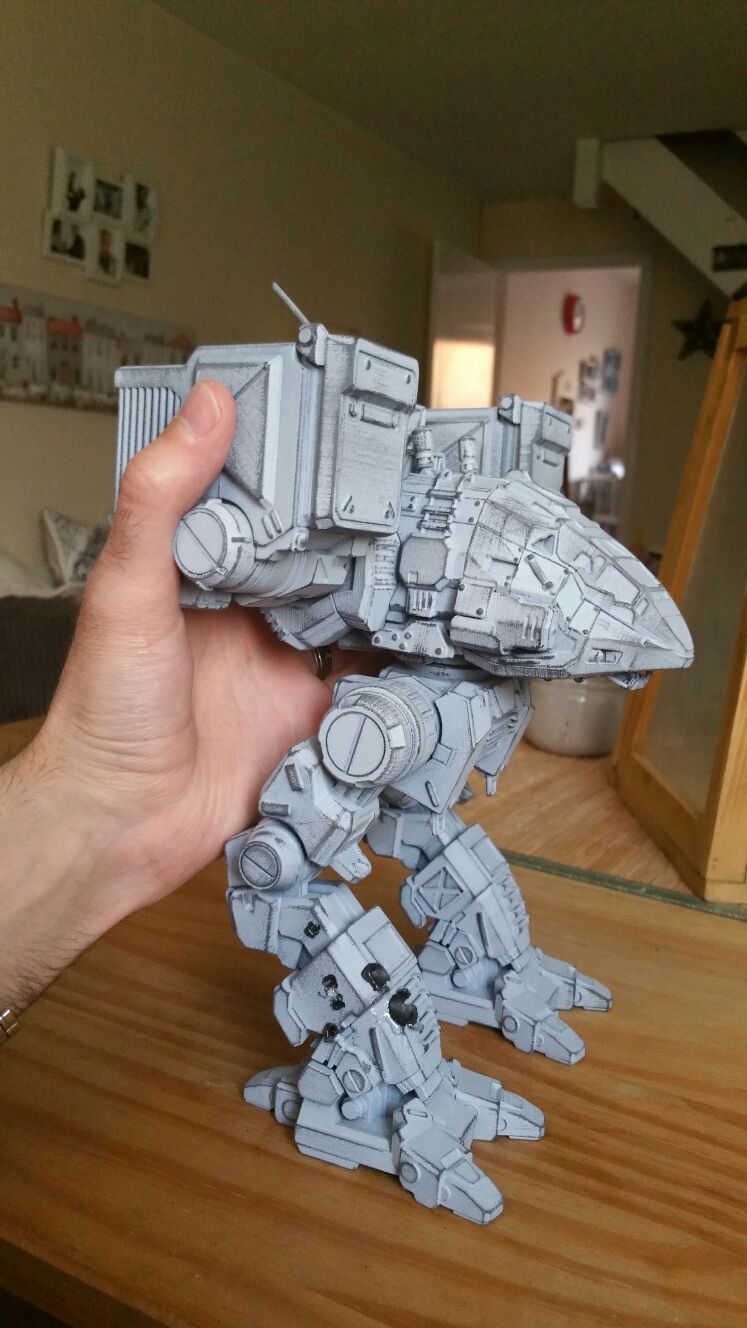

3D printing the case and lever

Use the following settings in your slicer software:

Slot MachineV2 – Front.stl – 0.2 layer height, 20% infill, supports touching build plate, brim. After printing, drill the holes that hold the handle with a 2.5mm drill and create a thread with a 3mm tap.

Slot MachineV2 – Back.stl– 0.2 layer height, 20% infill, no supports, brim

Slot MachineV2 – Diffuser.stl – 0.1 layer height, 20% infill, no supports, brim, print first 3 layers in white, change to black on the start of layer 4.

ball-handle.stl – 0.2 layer height, 20% infill, no supports, brim

matrix-handle.stl – 0.2 layer height, 20% infill, no supports, brim (2 required)

Assembling the lever

The lever assembly is screwed on to the side of the front using M3 screws. Use countersunk head (flat head) screws. Place the switch on the holder and run the wires to the inside of the case.

Adding the diffuser and display module

The display module should be a tight fit. If it is too tight, file it down a bit and if it is too loose, add some blue painters tape as padding on the inside of the case.

Wiring up the microprocessor and other components

I added a two pin right angle header to D2 and GND so that the button cable can be removed to separate the back panel.

The display board is connected to the microprocessor with nine wires:

The speaker is connected to D8 (-ve side) and D9 (+ve side).

Make sure you set the 3A regulator to output 5V BEFORE you wire it to the 5V rail of the Arduino Pro Mini.

Programming

You will need a FTDI module to program the Arduino Pro Mini (6 pin header). The FTDI module will connect to your USB port on your computer. Load up the Arduino IDE and set the board to a Arduino Pro Mini 5V 16Mhz and upload the sketch.

Final assembly

Read more